The characteristics of TLL brake roller sleeve pin coupling

Diaphragm coupling is by several groups of diaphragm (stainless steel thin plate) using bolt crisscross with half coupling, diaphragm composed of several pieces fold sets in each group, the diaphragm can be divided into connecting rod type and different shapes of the chip.

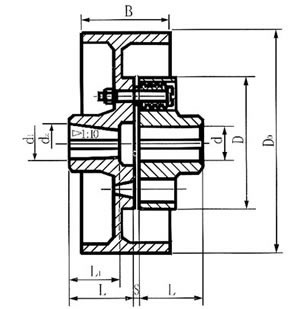

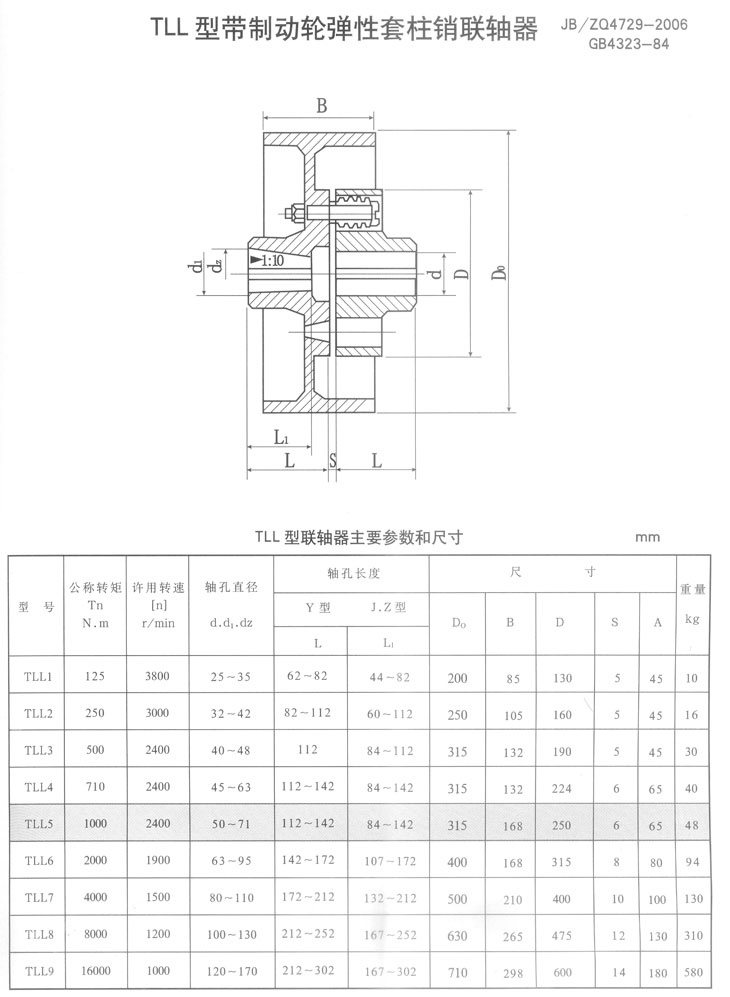

The elastic sleeve pin coupler is a pin with a flexible sleeve (rubber material) on one end, which is installed in the flange hole of the two-part coupler to realize the coupling of the two-and-a-half coupling. Column elastic sleeve pin coupling was once a coupling device of the most widely used in our country, as early as the late 1950 s, which is for the mechanical standards, JB08-60 elastic dowel pin coupling, is China's first standard coupling.

Low column elastic sleeve pin coupling structure is simple, manufacture easily, no lubrication, don't need and metal sulfide, change the elastic sleeve is convenient, need not move half coupling, two axis relative offset compensation and vibration damping buffer performance. Elastic sleeve work is subject to compression deformation, due to the thickness of the elastic sleeve thin, small size, elastic deformation is limited, so, although column elastic sleeve pin coupling can compensate the axis displacement and elastic, but axis allowable displacement compensation quantity is less, less elastic. The elastic sleeve pin coupling is based on the locking force of the column pin group to produce friction torque on the contact surface, and compressible rubber elastic sleeve to transfer torque. It is suitable for small and medium power shafts with high rigidity, high accuracy, low impact load and low demand for vibration reduction.

团结、创新、诚信、务实!

团结、创新、诚信、务实!  过硬的产品,优质的服务,合理的价格!

过硬的产品,优质的服务,合理的价格!  雄厚实力 科学管理、先进的营销理念和良好的信誉!

雄厚实力 科学管理、先进的营销理念和良好的信誉!