Diaphragm coupling is by several groups of diaphragm (stainless steel thin plate 1 cr18ni9) using bolt crisscross with half coupling, diaphragm composed of several pieces fold sets in each group, the diaphragm can be divided into connecting rod type and different shapes of the chip.

Low diaphragm coupling on the elastic deformation of the diaphragm to compensate for the two axes relative displacement, is a kind of high performance metal flexible coupling components elastic, no lubrication, structure is compact, high intensity, long service life, no rotating clearance, not influenced by temperature and oil pollution, has the characteristics of acid and alkali resistance, corrosion resistance, suitable for high temperature, high speed, a shaft transmission of working condition of corrosive medium environment, widely used in all kinds of shaft transmission of mechanical device, such as the pump (especially high power), chemical pump, fan, compressor, hydraulic machinery, petroleum machinery, printing machinery, textile machinery, chemical machinery, mining machinery, metallurgical machinery, aviation (helicopters), ships high-speed power transmission system, after dynamic balancing treatment applied in high-speed transmission shafting were common.

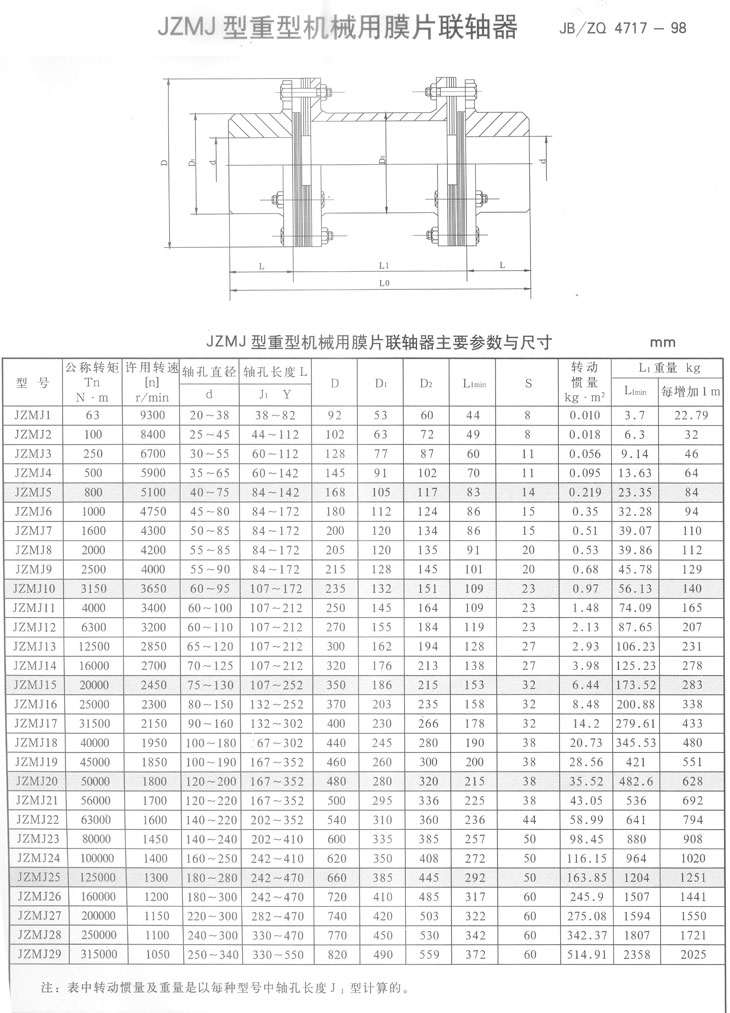

Type low JZMJ heavy machinery with the diaphragm coupling with high mechanical strength, large carrying capacity, light quality, structure, small size, transmission efficiency and high precision, good reliability, convenient installation, and has no relative sliding, without lubrication, no noise, long service life, acid, alkali, corrosion resistance, etc, can be used for high temperature, low temperature, and the operation condition of the oil, water and corrosive medium environment. Suitable for medium, high speed, high torque shafting transmission. And all kinds of mechanical device load change not small shafting transmission, the versatility.

Use and maintenance

Before installation, two axial surfaces should be cleaned to check the mating conditions of the end keyway.

When the diaphragm coupling is installed, it is necessary to check all the screws, such as loose and must be tightened, so as to ensure it will not be loose.

In order to prevent membrane micro wear in high speed, prompted a micro cracks and damage, diaphragm bolt hole in the diaphragm between coated with solid lubricant such as molybdenum disulfide or antifriction coating treatment on the surface of a diaphragm;

Long-term overloading and operation accidents should be avoided;

During the operation, it is necessary to check whether abnormal phenomena occur in the diaphragm couplings. If abnormal phenomenon occurs, it must be repaired and repaired.

Appropriate safety precautions must be taken at various sites that may cause personal and equipment accidents due to the operating diaphragm couplings.

团结、创新、诚信、务实!

团结、创新、诚信、务实!  过硬的产品,优质的服务,合理的价格!

过硬的产品,优质的服务,合理的价格!  雄厚实力 科学管理、先进的营销理念和良好的信誉!

雄厚实力 科学管理、先进的营销理念和良好的信誉!