团结、创新、诚信、务实!

团结、创新、诚信、务实!  过硬的产品,优质的服务,合理的价格!

过硬的产品,优质的服务,合理的价格!

雄厚实力 科学管理、先进的营销理念和良好的信誉!

雄厚实力 科学管理、先进的营销理念和良好的信誉!

对外贸易 自主研发 非标定制

团结、创新、诚信、务实!

团结、创新、诚信、务实!  过硬的产品,优质的服务,合理的价格!

过硬的产品,优质的服务,合理的价格!

雄厚实力 科学管理、先进的营销理念和良好的信誉!

雄厚实力 科学管理、先进的营销理念和良好的信誉!

对外贸易 自主研发 非标定制

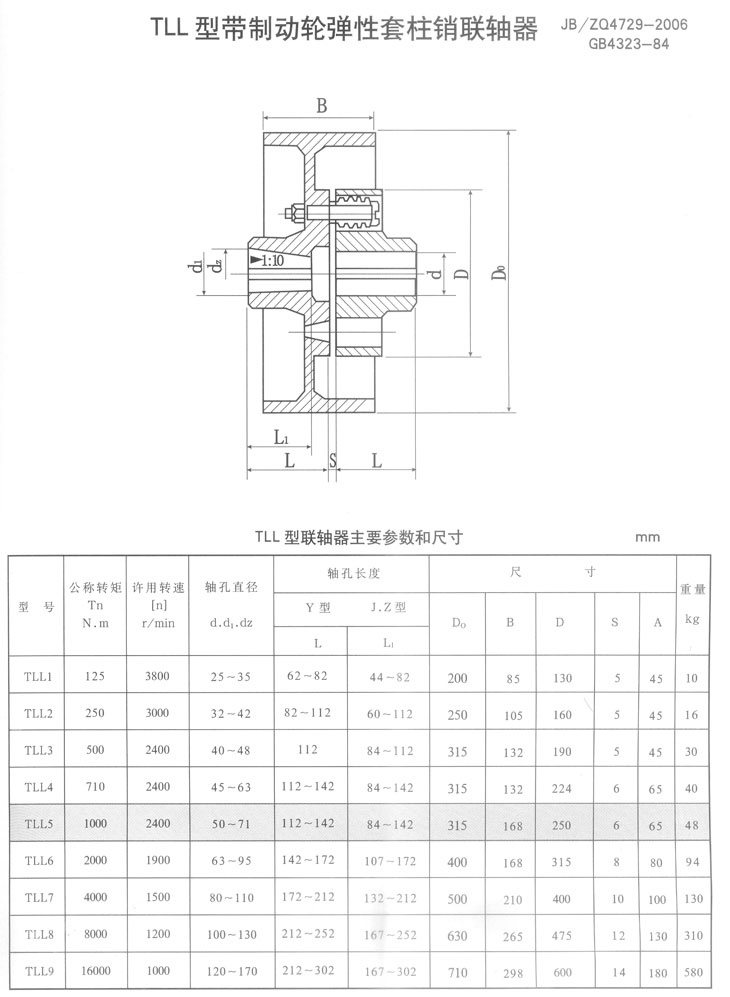

TLL带制动轮弹性套柱销联轴器的特点

●膜片联轴器是由几组膜片(不锈钢薄扳)用螺栓交错地与两半联轴器联接,每组膜片由数片叠集而成,膜片分为连杆式和不同形状的整片式。

●弹性套柱销联轴器是利用一端套有弹性套(橡胶材料)的柱销,装在两半联轴器凸缘孔中,以实现两半联轴器的联接。弹性套柱销联轴器曾经是我国应用最广泛的联轴 器,早在 20 世纪 50 年代末期即已制订为机械部标准, JB08 — 60 弹性圈柱销联轴器,是我国第一个部标准联轴器。

●弹性套柱销联轴器结构比较简单,制造容易,不用润滑,不需要与金属硫化粘结,更换弹性套方便,不用移动半联轴器,具有一定补偿两轴相对偏移和减振缓冲性能。 弹性套工作是受压缩变形,由于弹性套的厚度较薄,体积小,弹性变形有限,所以,弹性套柱销联轴器虽可补偿轴线位移和弹性,但轴线位移许用补偿量较少,弹性 较弱。弹性套柱销联轴器是依靠柱销组的锁紧力而产生于接触面的摩擦力矩,并压缩橡胶弹性套来传递转矩。适用于安装底座刚性好、对中精度较高、冲击载荷不 大、对减振要求不高的中小功率轴系传动。

The characteristics of TLL brake roller sleeve pin coupling

Diaphragm coupling is by several groups of diaphragm (stainless steel thin plate) using bolt crisscross with half coupling, diaphragm composed of several pieces fold sets in each group, the diaphragm can be divided into connecting rod type and different shapes of the chip.

The elastic sleeve pin coupler is a pin with a flexible sleeve (rubber material) on one end, which is installed in the flange hole of the two-part coupler to realize the coupling of the two-and-a-half coupling. Column elastic sleeve pin coupling was once a coupling device of the most widely used in our country, as early as the late 1950 s, which is for the mechanical standards, JB08-60 elastic dowel pin coupling, is China's first standard coupling.

Low column elastic sleeve pin coupling structure is simple, manufacture easily, no lubrication, don't need and metal sulfide, change the elastic sleeve is convenient, need not move half coupling, two axis relative offset compensation and vibration damping buffer performance. Elastic sleeve work is subject to compression deformation, due to the thickness of the elastic sleeve thin, small size, elastic deformation is limited, so, although column elastic sleeve pin coupling can compensate the axis displacement and elastic, but axis allowable displacement compensation quantity is less, less elastic. The elastic sleeve pin coupling is based on the locking force of the column pin group to produce friction torque on the contact surface, and compressible rubber elastic sleeve to transfer torque. It is suitable for small and medium power shafts with high rigidity, high accuracy, low impact load and low demand for vibration reduction.