团结、创新、诚信、务实!

团结、创新、诚信、务实!  过硬的产品,优质的服务,合理的价格!

过硬的产品,优质的服务,合理的价格!

雄厚实力 科学管理、先进的营销理念和良好的信誉!

雄厚实力 科学管理、先进的营销理念和良好的信誉!

对外贸易 自主研发 非标定制

团结、创新、诚信、务实!

团结、创新、诚信、务实!  过硬的产品,优质的服务,合理的价格!

过硬的产品,优质的服务,合理的价格!

雄厚实力 科学管理、先进的营销理念和良好的信誉!

雄厚实力 科学管理、先进的营销理念和良好的信誉!

对外贸易 自主研发 非标定制

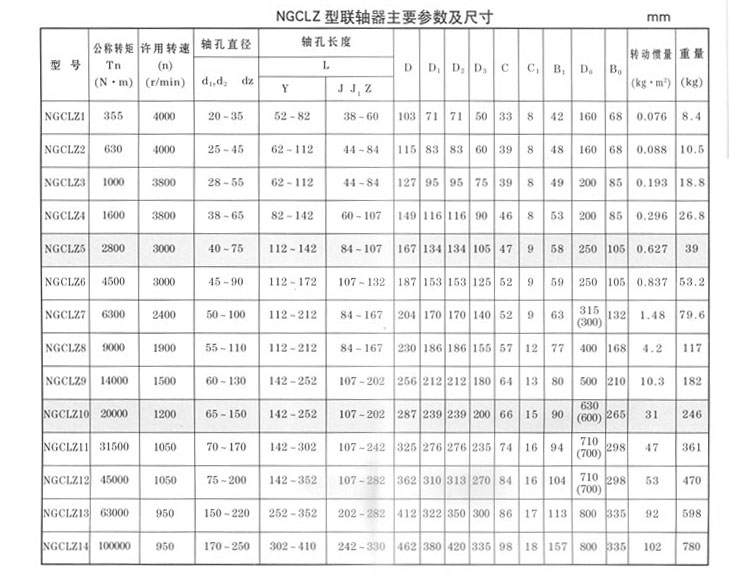

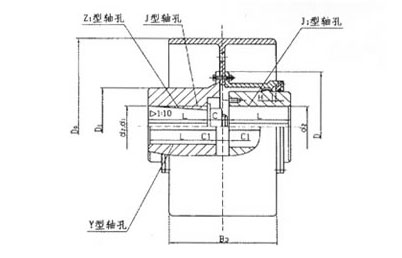

NGCLZ型带制动轮鼓形齿式联轴器,适用于联接两水平同轴线传动轴系,传递公称扭矩为355~100000KN.m,

鼓形齿式联轴器属于刚挠性联轴器,齿式联轴器是由齿数相同的内齿圈和带外齿的凸缘半联轴器等零件组成。外齿分为直齿和鼓形齿两种齿形,所谓鼓形齿即为将外齿制成球面,球面中心在齿轮轴线上,齿侧间隙较一般齿轮大,鼓形齿联轴器可允许较大的角位移(相对于直齿联轴器),可改善齿的接触条件,提高传递转矩的能力,延长使用寿命。有角位移时沿齿宽的接触状态。具有径向、轴向和角向等轴线偏差补偿能力,具有结构紧凑、回转半径小、承载能力大、传动效率高、噪声低及维修周期长等优点,特别适用于低速重载工况,如冶金、矿山、起重运输等行业、也适用于石油、化工、通用机械等各类机械的轴系传动

齿式联轴器在工作时,两轴产生相对角位移,内外齿的齿面周期性作轴向相对滑动,必然形成齿面磨损和功率消耗,因此,齿式联轴器需在有良好和密封的状态下工作。齿式联轴器径向尺寸小,承载能力大,常用于低速重载工况条件的轴系传动,高精度并经动平衡的齿式联轴器可用于高速传动,如燃汽轮机的轴系传动。由于鼓形齿式联轴器角向补偿大于直齿式联轴器,国内外均广泛采用鼓形齿式联轴器,直齿式联轴器属于被淘汰的产品,选用者应尽量不选用。

鼓形齿式联轴器的特点(与直齿式联轴器相比有以下特点) :

1、承载能力强。在相同的内齿套外径和联轴器最大外径下,鼓形齿式联轴器的承载能力平均比直齿式联轴器提高15~20%

2、角位移补偿量大。当径向位移等于零时,直齿式联轴器的许用角位移为1o,而鼓形齿式联轴器的许用角位移为1o30',提高50%。在相同的模数、齿数、齿宽下,鼓形齿比直齿允许的角位移大,

3、鼓形齿面使内、外齿的接触条件得到改善,避免了在角位移条件下直齿齿端棱边挤压,应力集中的弊端,同时改善了齿面摩擦、磨损状况,降低了噪声,维修周期长。

4、外齿套齿端呈喇叭形状,使内、外齿装拆十分方便。

5、传动效率高达99.7%。

基于经上特点,目前,国内外已普遍以鼓形齿替代直齿式联轴器。

The NGCLZ type band brake drum gear coupling is suitable for connecting the two horizontal coaxial transmission shafts, transmitting the nominal torque to 355 ~ 100000KN. M,

The drum gear coupling is a flexible coupling, and the gear coupling is made up of the same inner tooth ring and the flange half coupling of the outer tooth. Divided into straight teeth and drum tooth outside two kinds of tooth shape, tooth is the so-called drum will made spherical outer teeth, spherical center on the gear axis, backlash is generally large gear, drum gear couplings allows a larger angular displacement (as opposed to straight tooth coupling), can improve the tooth contact conditions, improve the ability to transfer torque, prolong service life. The contact state along the tooth width in angular displacement. Radial, axial and angular axis deviation compensation ability, has a compact structure, small turning radius, large carrying capacity, high transmission efficiency, low noise and long maintenance cycle, especially suitable for the condition of low speed and heavy loading, such as metallurgy, mining, lifting transportation and other industries, can also be applied to petroleum, chemical industry, general machinery and other kinds of shaft transmission of machine

Type coupling at work, two relative angular displacement of the shaft of the internal and external gear tooth surface of periodic axial relative sliding, inevitable formation of tooth surface wear and power consumption, therefore, the coupling should be in good and sealing state work. Type coupling radial size is small, large carrying capacity, often used for shaft transmission of working condition of low speed and heavy loading, high precision and the dynamic balance of coupling can be used for high-speed transmission, such as gas turbine shaft transmission. Because the drum type coupling Angle is greater than the direct coupling to the compensation, both at home and abroad widely used drum type coupling, straight type coupling are eliminated products, choose those should not choose as far as possible.

The characteristics of drum gear coupling (compared with the straight gear coupling) :

1. Strong carrying capacity. The load capacity of drum gear coupling is 15 ~ 20% higher than that of the straight gear coupling in the same inner tooth casing and the coupling maximum outside diameter

2. The offset of angular displacement is large. When the radial displacement is equal to zero, the allowable angular displacement of the direct tooth coupling is 1o, while the allowable angular displacement of the drum gear coupling is 1o30 ', which is increased by 50%. Under the same modulus, teeth, and width of the teeth, the drum teeth are larger than the allowed angular displacement of the straight teeth.

3, drum gear tooth surface of internal and external tooth contact conditions improved, avoided under the condition of angular displacement straight tooth gear tooth edge extrusion, the disadvantages of stress concentration, and at the same time improve the tooth surface friction, wear, reduced the noise, maintenance cycle is long.

4. The outer teeth of the outer teeth are honked in shape, making it convenient for the inside and outer teeth to be removed.

5. The transmission efficiency is up to 99.7%.

Based on the characteristics of the current, it is widely used to replace the straight tooth coupling with drum teeth.