团结、创新、诚信、务实!

团结、创新、诚信、务实!  过硬的产品,优质的服务,合理的价格!

过硬的产品,优质的服务,合理的价格!

雄厚实力 科学管理、先进的营销理念和良好的信誉!

雄厚实力 科学管理、先进的营销理念和良好的信誉!

对外贸易 自主研发 非标定制

团结、创新、诚信、务实!

团结、创新、诚信、务实!  过硬的产品,优质的服务,合理的价格!

过硬的产品,优质的服务,合理的价格!

雄厚实力 科学管理、先进的营销理念和良好的信誉!

雄厚实力 科学管理、先进的营销理念和良好的信誉!

对外贸易 自主研发 非标定制

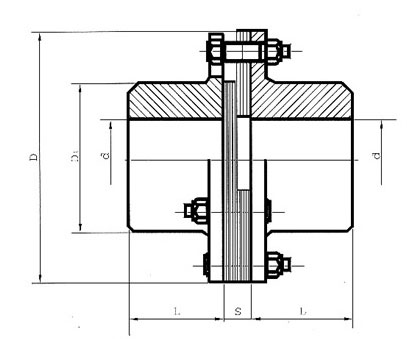

●膜片联轴器是由几组膜片(不锈钢薄扳1Cr18Ni9)用螺栓交错地与两半联轴器联接,每组膜片由数片叠集而成,膜片分为连杆式和不同形状的整片式。

●膜片联轴器靠膜片的弹性变形来补偿所联两轴的相对位移,是一种高性能的金属弹性元件挠性联轴器,不用润滑,结构较紧凑,强度高,使用寿命长,无旋转间隙,不受温度和油污影响,具有耐酸、耐碱、防腐蚀的特点,适用于高温、高速、有腐蚀介质工况环境的轴系传动,广泛用于各种机械装置的轴系传动,如水泵(尤其是大功率、化工泵)、风机、压缩机、液压机械、石油机械、印刷机械、纺织机械、化工机械、矿山机械、冶金机械、航空(直升飞机)、舰艇高速动力传动系统,经动平衡处理后应用于高速传动轴系已比较普遍。

●JZMJ型重型机械用膜片联轴器具有机械强度高、承载能力大、质量轻、结构尺寸小,传动效率和传动精度高、可靠性好、装拆方便,且具有无相对滑动,不需润滑,使用寿命长、无噪声、耐酸、碱、防腐蚀等特点,可用于高温、低温和有油、有水和腐蚀介质的工况环境。适用于中、高速、大转矩轴系传动。以及各种机械装置载荷变化不大的轴系传动,通用性极强。

使用与保养

安装前,应清洗两轴端面,检查端面键槽口等配合情况;

膜片联轴器安装以后,正常运转一个班,必须检查所有螺钉,如发现松动,必须拧紧,这样反复几个班,以保证不会松动;

为了防止膜片在高速运转发生的微动磨损,导致膜片螺栓孔出现微裂而损坏,可在膜片之间涂以二硫化钼等固体润滑剂或对膜片表面进行减磨涂层处理;

应避免长期超载使用和操作事故的发生;

在工作运转中,应经常检查膜片联轴器是否发生异常现象,如有异常现象发生必须及进维修;

在可能由于运转的膜片联轴器引起人身和设备事故的各个场地必须采取适当的安全防护措施。

Diaphragm coupling is by several groups of diaphragm (stainless steel thin plate 1 cr18ni9) using bolt crisscross with half coupling, diaphragm composed of several pieces fold sets in each group, the diaphragm can be divided into connecting rod type and different shapes of the chip.

Low diaphragm coupling on the elastic deformation of the diaphragm to compensate for the two axes relative displacement, is a kind of high performance metal flexible coupling components elastic, no lubrication, structure is compact, high intensity, long service life, no rotating clearance, not influenced by temperature and oil pollution, has the characteristics of acid and alkali resistance, corrosion resistance, suitable for high temperature, high speed, a shaft transmission of working condition of corrosive medium environment, widely used in all kinds of shaft transmission of mechanical device, such as the pump (especially high power), chemical pump, fan, compressor, hydraulic machinery, petroleum machinery, printing machinery, textile machinery, chemical machinery, mining machinery, metallurgical machinery, aviation (helicopters), ships high-speed power transmission system, after dynamic balancing treatment applied in high-speed transmission shafting were common.

Type low JZMJ heavy machinery with the diaphragm coupling with high mechanical strength, large carrying capacity, light quality, structure, small size, transmission efficiency and high precision, good reliability, convenient installation, and has no relative sliding, without lubrication, no noise, long service life, acid, alkali, corrosion resistance, etc, can be used for high temperature, low temperature, and the operation condition of the oil, water and corrosive medium environment. Suitable for medium, high speed, high torque shafting transmission. And all kinds of mechanical device load change not small shafting transmission, the versatility.

Use and maintenance

Before installation, two axial surfaces should be cleaned to check the mating conditions of the end keyway.

When the diaphragm coupling is installed, it is necessary to check all the screws, such as loose and must be tightened, so as to ensure it will not be loose.

In order to prevent membrane micro wear in high speed, prompted a micro cracks and damage, diaphragm bolt hole in the diaphragm between coated with solid lubricant such as molybdenum disulfide or antifriction coating treatment on the surface of a diaphragm;

Long-term overloading and operation accidents should be avoided;

During the operation, it is necessary to check whether abnormal phenomena occur in the diaphragm couplings. If abnormal phenomenon occurs, it must be repaired and repaired.

Appropriate safety precautions must be taken at various sites that may cause personal and equipment accidents due to the operating diaphragm couplings.